Compact-Feeder

Compact-Feeders have an increased wall thickness compared to classic insert sleeves. The resulting increased exothermic reaction makes it possible to reduce the volume of the inner feeder and thus leads to improved output.

This effect is supported by the good insulation properties of the Cold-Box-bonded formulations. This product range is part of the classic feeder systems and is suitable both for moulding onto the pattern plate and for core shooting.

Benefits of Compact-Feeders

Compact-Feeders were developed as an alternative to classic feeder caps. Due to their more complex geometry, as well as the development of innovative bulk formulations, the Chemex Compact-Feeders offer a wide range of benefits for our customers:

Lower scrap rates

Lower melting costs

Fluorine-free formulations

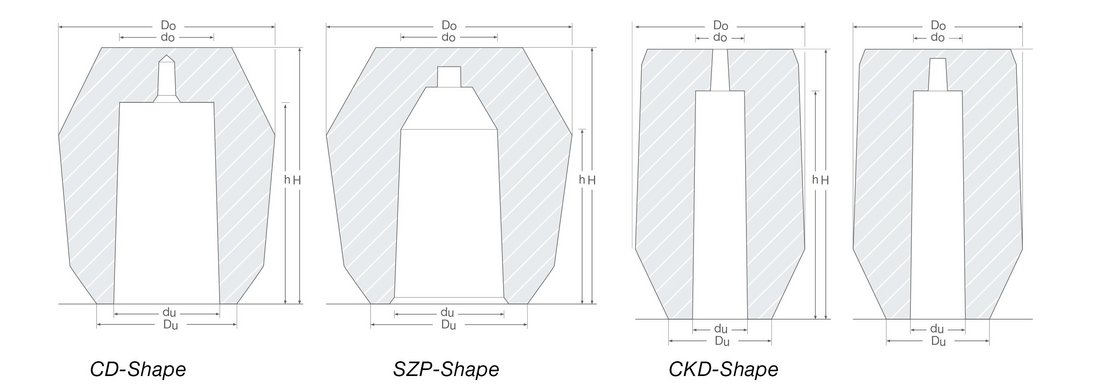

Optimised outer geometries

Higher yields

Smaller footprints