Side-Insert-Sleeve

The Side-Insert-Sleeve is one of the latest developments from Chemex Foundry Solutions GmbH. It has been developed mainly for customers who use vertically partitioned moulding lines. The biggest advantage of this one-piece feeding system is its easy and automatable positioning in the mould face with the help of the core inserter.

In addition to the air removal via the feeder at the partition level, the system also achieves an increase in output. In many cases, this increases the efficiency of pattern plate layouts.

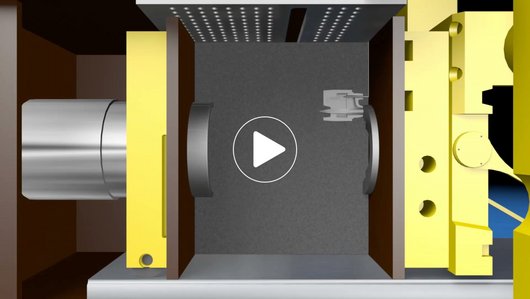

Tele-Side-Riser

With the Tele-Side-Riser system, Chemex has made its innovative, proprietary telescopic technology available for vertical moulding lines, including all of the advantages of our classic Tele-Feeder-System, such as high-volume output and low fettling effort thanks to its minimal footprint.

As with our Side-Insert-Sleeve, air can be discharged via the mould partition. The system’s improved output allows more or larger castings to be placed on the pattern plate.

Tele-Feeder

The two-part Tele-Feeder-System is a Chemex invention and also our flagship feeding solution. The greatest advantage of this system is its innovative telescopic technology, in which the upper section slides over the lower section during the moulding process.

This guarantees enhanced compaction of the moulding sand below the feeder, while also allowing the system to absorb much of the energy of the compaction pressure. The lower section is thus protected from the compaction pressure, thereby creating a defined break-off point, which minimizes releasing and cleaning costs.

Tele-Shell-Feeder (Tele-SF-System)

The Tele-Shell-Feeder from Chemex combines the advantages of the Tele-Feeder-System with those of a classic spherical feeder. The thermodynamically favorable spherical shape creates an optimal ratio between volume and surface area.

In combination with a short feeder neck, significantly lower riser heights can be generated compared to the traditional Tele-Feeder-System. The Tele SF is therefore particularly suitable for use on molding lines with low cope heights.

ExoPlast

With this self-curing system, it is possible to test exothermic and insulating sleeve material in prototype casting or small series. No gassing or heating is required.

The system can be molded manually like sand or, for example, pressed into a 3D printed plastic mold to produce a contour breaker core.