Innovative Tele-Feeder Technology

The Chemex Tele-Feeder System has more than proven its worth, especially in horizontally parted moulding lines subject to high pressure resistance.

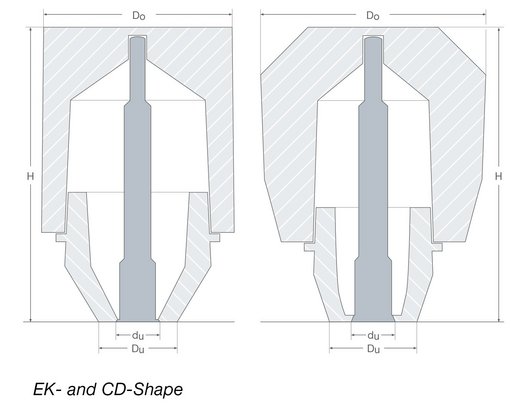

After placing the feeder on the pattern plate, the upper section of the feeder slides telescopically over the lower section during the compaction process. This means that the lower section is practically not exposed to pressure, and therefore, damage.

The Chemex Tele-Feeder System has not only proved itself in hand moulding, but also with all common alloys in the non-ferrous sector, for cast iron and steel casting.

Higher output, lower separation and cleaning costs

At the same time, shifting the upper part leads to additional compaction of the moulding sand underneath (transition area between feeder and casting), precisely where shadows of poorly compacted sand may occur in other feeding systems. The range of applications of the Tele-Feeder System has been extended over the years. With its Tele(scopic)-Feeder technology, Chemex has developed a highly effective solution that is being used by more and more foundries every day.

Find out more about how the Tele-Feeder-System works.

Benefits of the Tele-Feeder-System

Tele-Feeders were primarily developed for horizontal moulding lines. Thanks to their proprietary telescopic technology and the ongoing development of innovative formulations and geometries, Chemex Tele-Feeders offer a range of significant advantages for our customers:

Higher yields

Lower melting costs

Lower scrap rates

Fluorine-free formulations

Minimal contact area to the casting

Less fettling required

Heated feeder neck

Use of maintenance-free positioning aid